chassis cnc automatic bending machine

Loading process with a 40HQ

Customer feedback

Customer from diffrenet countries come for inspection and cooperation

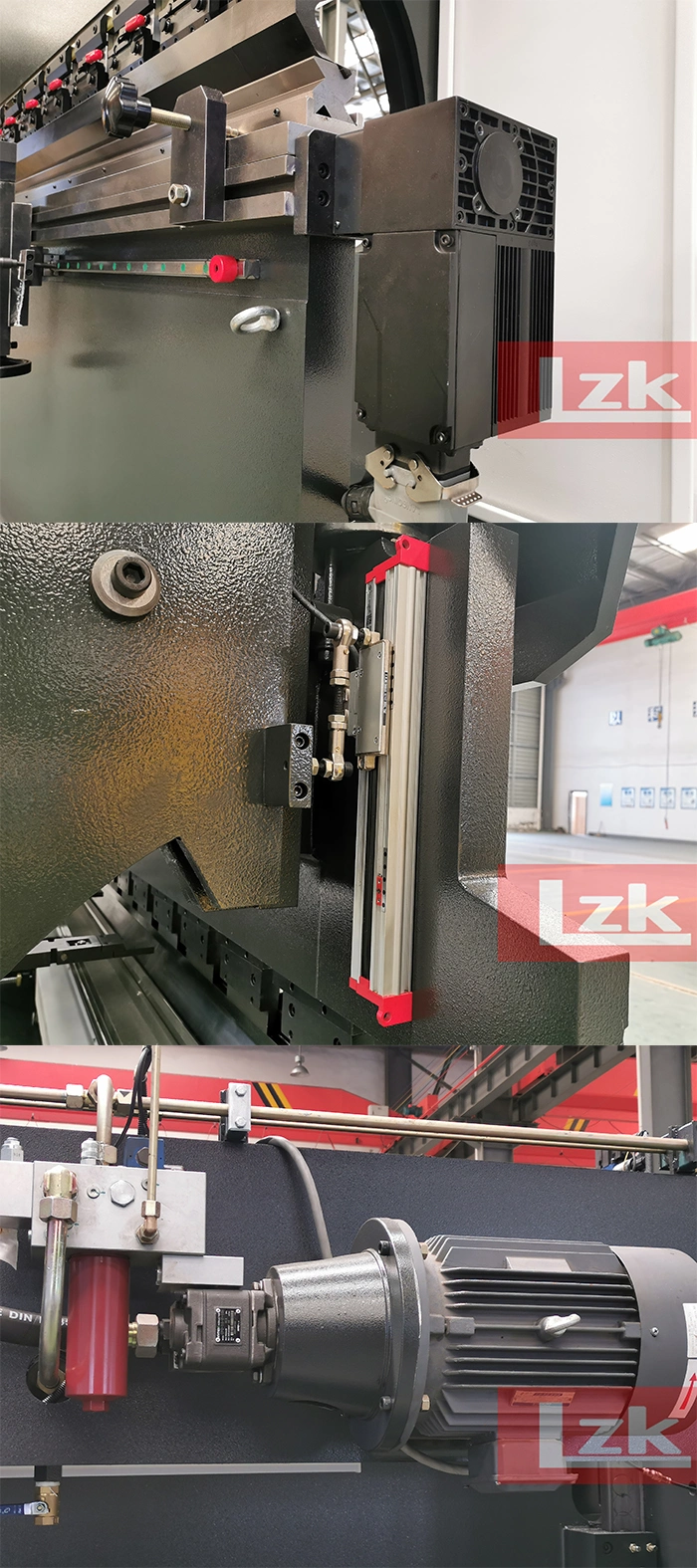

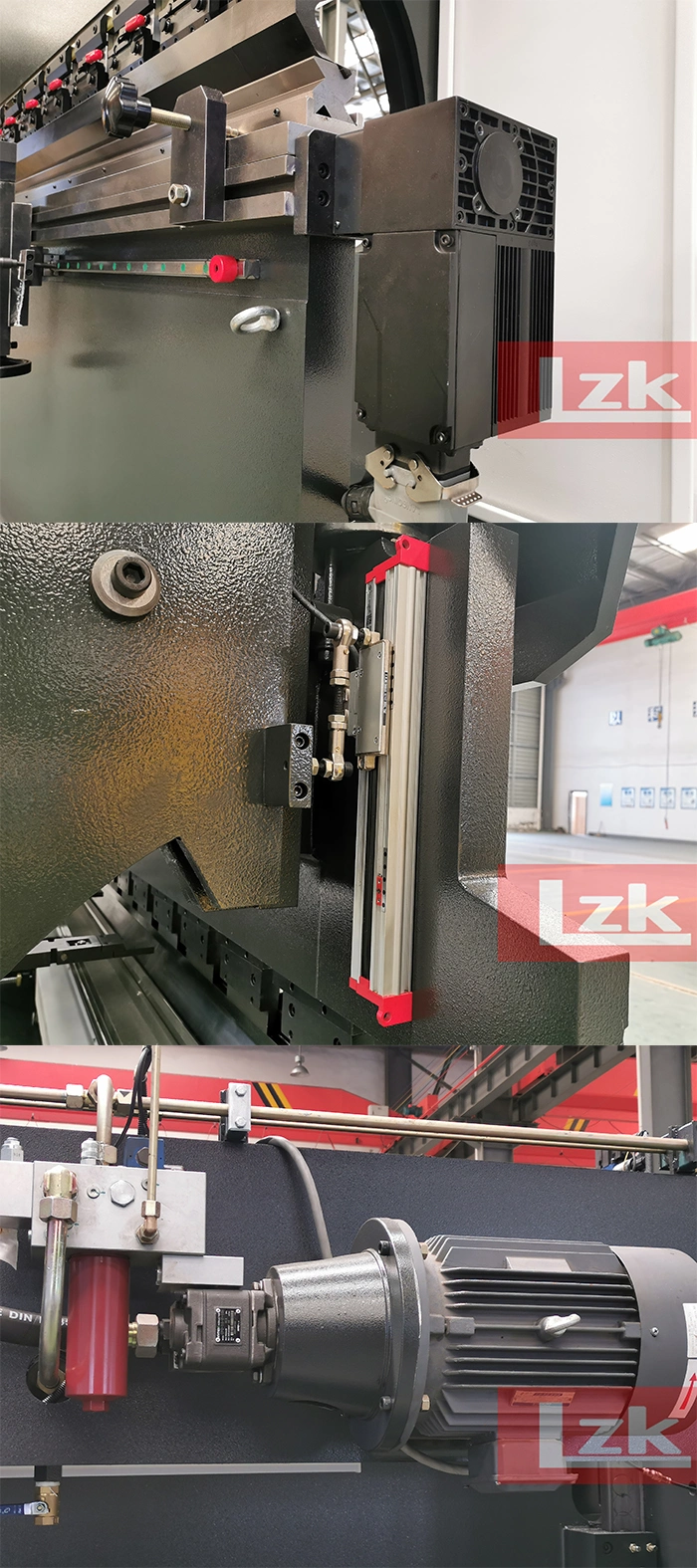

| The frame is made of steel structure, left and right vertical plate, worktable and pressure plate are welded into a whole structure. After welding, the internal stress is eliminated by tempering, so the whole steel is good and the stability is high. |

| Latest high-frequency responding hydraulic control technology, faster, more efficient and accurate. |

| DELEM DA66T CNC control system |

| KACON footpedal |

| One set of punch and die with machine, we can also design if customer has special demand for tool |

| Sliding front support arms, easy to handle |

| Special designed type bottom for more stable machine body |

| Quick clamp |

| Automatic crowning through cnc system |

| Italy GIVI grating ruler |

| Bosch-Rexroth hydraluic system, Sunny oil pump, and Siemens main motor |

| Schneider main electrical components |

| Japan YASKAWA servo drive |

| Backgauge with X, R, Z1, Z2 axes |

| Servo motor controlled backgauge |

| Double linear guide rails |

Customer feedback

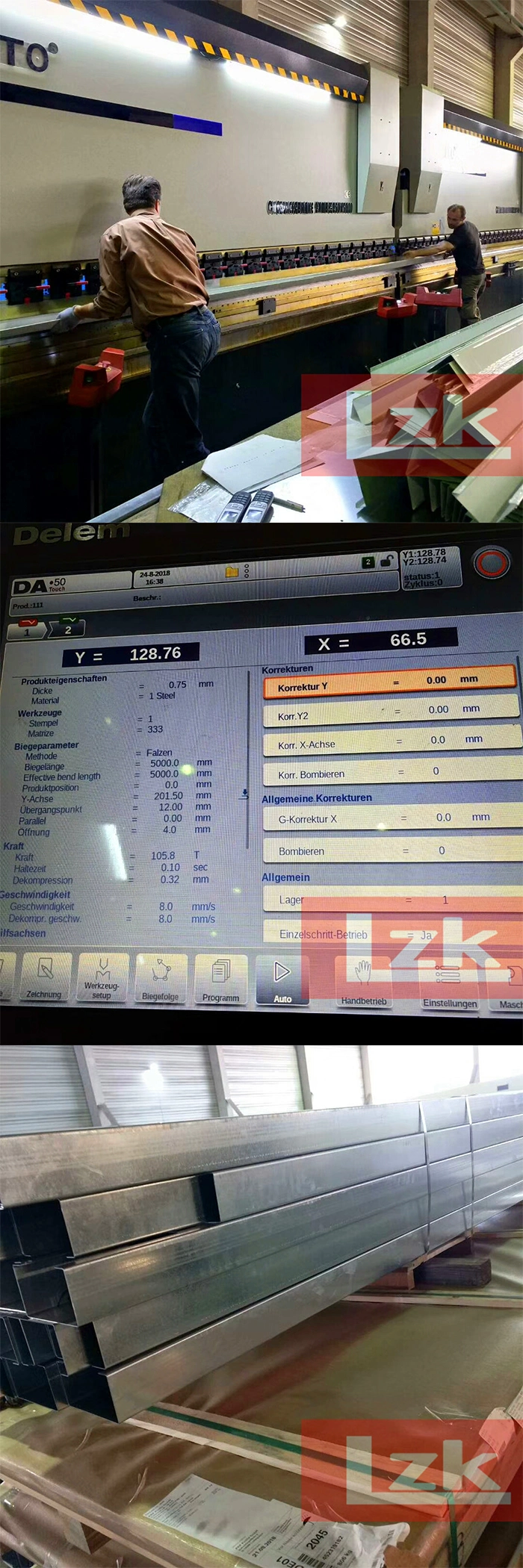

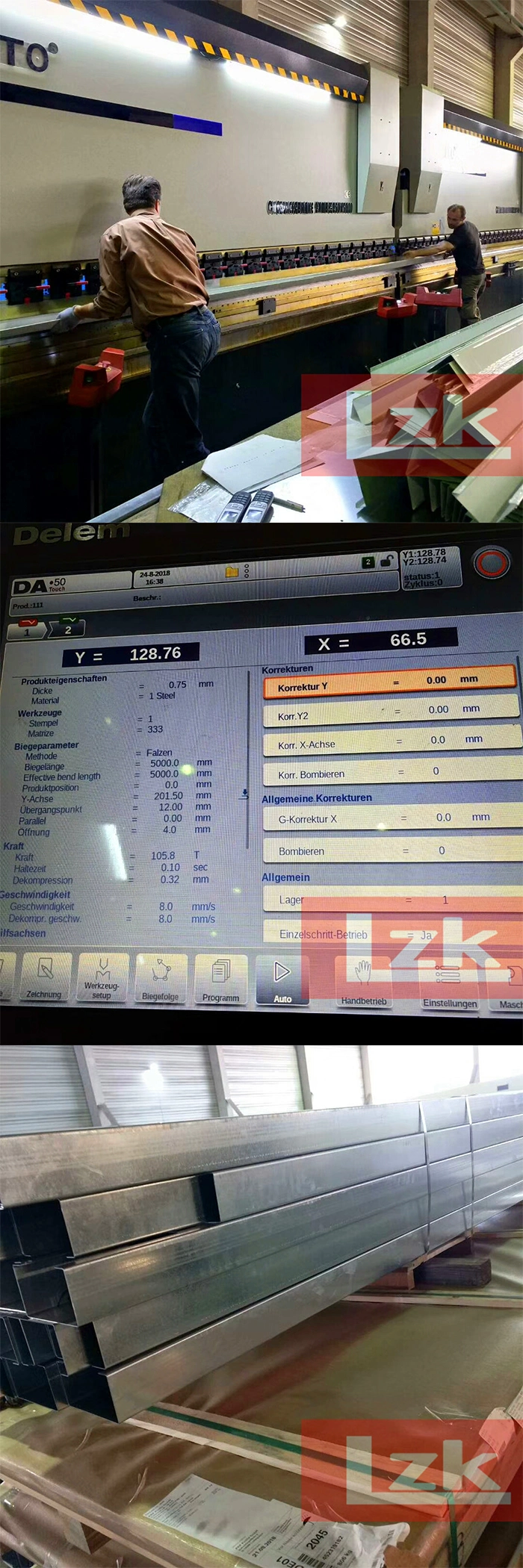

| German Customer with Tandem Press Brake for long sheet bending |

| Russia Customer, manufacturer of Yacht |