Customer's needs and satisfaction is what we are constantly creating and pursuing

This machine combines process of bottom flanging, bottom & top seaming to achieve full automatic 1-5L small round can making.

It adopts cam transmission system and jam protection feature that help the machine run more smoothly, produce best finished cans with highest efficiency.

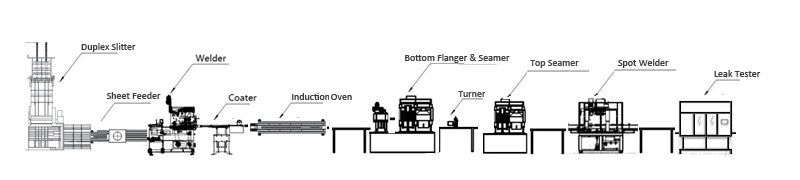

1-5L Small Round Can Making Line

Technical Parameters:

Multi-function Combiner (Flanging-Seaming-Seaming)

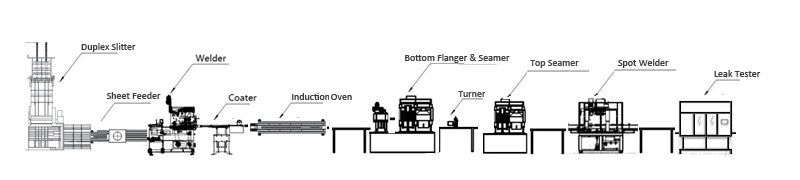

Duplex Slitter

Tinplate Feeder

Welder

External & Internal Coater

Induction Drying Oven

Auto Seamer

Auto Spot Welder

-Original manufacturer with 18-year professional can making experience.

-Customized Equipments according to customer' requirements, high quality with competitive price.

-Abundant export experience: our products have been exported to Indonesia, Malaysia, Vietnam, Singapore,

Iran, Turkey, India, Poland, Italy, etc.

-Superior after-sale service: Engineers available to service machinery overseas.

This machine combines process of bottom flanging, bottom & top seaming to achieve full automatic 1-5L small round can making.

It adopts cam transmission system and jam protection feature that help the machine run more smoothly, produce best finished cans with highest efficiency.

1-5L Small Round Can Making Line

Technical Parameters:

Multi-function Combiner (Flanging-Seaming-Seaming)

| Applicable Can Type | 1-5L small round can |

| Capacity | 60-80cpm |

| Can Diameter | D60-D180mm |

| Can Height | D65-D320mm |

| Weight | Approx. 6 tons |

| Tinplate Thickness | 0.16-0.4mm |

| Overall Dimension | 3500x1500 x2200mm |

Duplex Slitter

| Max. Cutting Speed | 1130mm/s |

| Tolerance | ±0.05mm |

| Max. Sheet Feeding Speed | 40 spm |

| Max. Sheet Size | 1140mm×1140mm |

| Min. Sheet Size | 500mm×700mm |

| Max. Sheet Thickness | 0.4mm |

| Total Power | 6kW |

| Power Supply | Three Phase Voltage 380V 50HZ |

| Weight | 6000kg |

| Overall Dimension(L×W×H) | 6970×3000×1700mm |

Tinplate Feeder

| Max. Feeding | 800s pm |

| Applicable Can Diameter | Ф220-300mm |

| Applicable Can Height | H250-450mm |

| Total Power | 2kW |

Welder

| Welding Speed | 6 to 26m/min |

| Output Capacity | 20 to 60 cpm |

| Can Diameter | D52-D180mm |

| Can Height | H70-H330mm |

| Copper Wire Diameter | 1.5mm |

| Sheet Thickness | 0.25-0.6mm |

| Compressed Air | 0.6 Mpa |

| Power Supply | 380V±5% 50Hz |

| With Nitrogen Protection System. | |

External & Internal Coater

| Capacity | Up to 20m/min |

| Air Consumption | 0.6Mpa, 20L/min |

| Power | 0.5 kW |

Induction Drying Oven

| Can Diameter | #401D-#502D |

| Capacity | Up to 20m/min |

| Heater Length | 0.8 m/ Heater |

| Sensing Distance | 5-20mm |

| Induction Width | 35-40mm |

| Heater | Double Coils |

| Rising Time | 6 Secs - 280 °C |

| Control | Individual Control |

| Total Length | Around 10 m |

| Running Type | Upper Suction |

| Chilling Type | Natural Chilling System |

Auto Seamer

| Applicable Can Type | 1-5L small round can |

| Capacity | 60-80cpm |

| Can Diameter | D60-D180mm |

| Can Height | D65-D320mm |

| Weight | Approx. 2.5 tons |

| Tinplate Thickness | 0.16-0.4mm |

| Overall Dimension | 1500x1500 x2200mm |

Auto Spot Welder

| Capacity | 60-80cpm |

| Can Diameter | D60-D180mm |

| Can Height | D65-D320mm |

| Weight | Approx. 2.5 tons |

| Tinplate Thickness | 0.16-0.4mm |

| Overall Dimension | 2100x1700 x2100mm |

-Original manufacturer with 18-year professional can making experience.

-Customized Equipments according to customer' requirements, high quality with competitive price.

-Abundant export experience: our products have been exported to Indonesia, Malaysia, Vietnam, Singapore,

Iran, Turkey, India, Poland, Italy, etc.

-Superior after-sale service: Engineers available to service machinery overseas.