1050-Straight line Folding Gluing Machine

Characteristics:

1.Driving by synchronous belt,ensure smooth and accurate running.

2.Inverter driving,stable and power saving.

3.Use electric adjust,easy operate.

4.Automatic continuous feeding,use multiple belt with vibrating motor,(for higher configuration use drilled suction belt),to keep the feeding stable.

5.Automatic counting and kicking,quantity can preset.

6.Conveyer pressure adjustable according to the box to ensure best quality.

2. Main technical parameter:

Machine configuration

5.Feature:

1.Feeder Section

· Friction feeder. Independently driven by inverter.

Adjustable electronic pile vibrator.

· Lateral feed gates fully adjustable to the width of the blank.

2.Paper Alignment System:

Independent section that registers the blank to one side ensuring a perfect parallelism before entering the pre-folding or gluing sections.

Independently driven by motor.

Possibility to register on any side of the machine.

Fast and easy setup.Configuration reducer, different boxes when the conversion, the reducer with electric regulation

Left hand glue flap pre-folder up to 180º.

3rd crease pre-folding set up to 135º.

1st and 3rd crease openers.

Configuration reducer, different boxes when the conversion, the reducer with electric regulation

4.Bottom Lock Section (option )

Lock-bottom assembly mechanism with high elastic hookers is of deal design,fast and easy operation.

·Independently driven by motor.

Complete set of folding hooks and helixes for smooth and accurate folding of front flaps

Adjustable hook tension.

Fast and easy setup

Configuration reducer, different boxes when the conversion, the reducer with electric regulation.

5.Down Gluing section

·Two lower (left and right) gluing tanks.

·Easy to remove and clean.

Smooth and accurate folding of 2nd and 4th creases.

Outer folding belts adjustable up to 180º with variable speed controlled by inverter

Easy accessibility.

· Upper and lower drive mechanism for length adjustment.

·Allows a perfect understack or overstack stream of boxes.

·Equipped with automatic belt tension-adjusting system.

·Continuous and automatic box collection mechanism that ensures a neat transfer to the Press section, guaranteeing an aligned flow.

8.Press Section

·Independently motorized pneumatic press section.

· Upper section moves back and forward through a motorized system, allowing different box length.

· Pneumatic pressure regulation.

·Two independent servo motors, one for each shaft.

·Versatile and easy to setup.

Gluing system

1. Main technical parameter:

Model HZ4

Plasma Surface Treatment

Main technical parameter:

>>> RFQ

1.Q:What is the machine warranty?

A:one year.

2.Q:Does your machine with CE certificate?

A:Yes.we do.

3.Q:What is the production time while placing order?

A:About 30 days.

4.Q:What is the delivery time?

A:Within 30 days after get the payment.

5.Q:Can your company handle shipping for customers?

A:Yes.(Please provide us your requested seaport and we can check the shipping charge and arrange shipping for your order)

6.Q:How about after-sales service process?

A:When your machine has problem, contact your sales and we will solve your problem soon as possible.

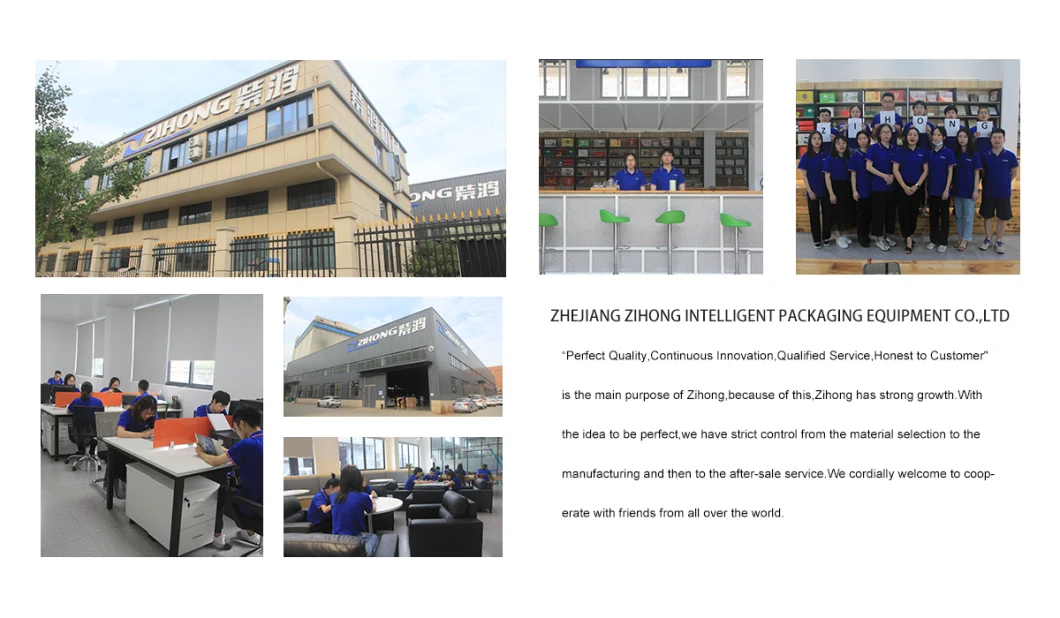

7.Q:Are you manufacturer?

A:Yes, we are manufacturer with 10-year experience and profession.

8.Q:Do you have stock product to sell?

A:Actually our machine need 20-30 days to manufacture, and there are many orders from China and foreign countries, so we need custom one for you, and your order will be highly attention to manufacture.

9.Q:Do you inspect the finished products?

A:Yes, we have QC department, they will inspect the machine before shipping, to ensure there is nothing problem of the machine .

10.Q:What's the payment term?

A:T/T 30% in advance, the balance paid before delivery. We also accept payment via West Union and L/C.

11.Q:Are you a trading company or factory?

A: We are the manufacturer and also we have import export license. We have specialized in folding gluing and window patching machine producing for more than 10 years.

12.Q:Where is your company located? How can I visit there?

A:Our new factory address: No.88 Lindong Road,Dongshang Industrial Area,Ruian City.Zhejiang province,China. Zhejiang Zihong Printing Packaging Machinery Co., LTD

13.Q: Can you send technician for installation and training?

A:Yes, we can send our technician abroad for installation and training, but all the charges must be paid by buyer, such as the plane tickets (around trip), meals, hotel, traffic etc.

14. What's your advantages ?

--Rich experience and profession.

--Customers all over the world

--Certificate: CE certificate

--Fast reply:Our team will reply you soon.

--Aftersale service:We have a after sale department, service for your problems and dealing with spare parts.

Any Need ,PLS send inquiry to us, we will be of service at any time.^•^ ^•^ ^•^

Characteristics:

1.Driving by synchronous belt,ensure smooth and accurate running.

2.Inverter driving,stable and power saving.

3.Use electric adjust,easy operate.

4.Automatic continuous feeding,use multiple belt with vibrating motor,(for higher configuration use drilled suction belt),to keep the feeding stable.

5.Automatic counting and kicking,quantity can preset.

6.Conveyer pressure adjustable according to the box to ensure best quality.

2. Main technical parameter:

| Model | ZH-M1050-S |

| Suitable material | Card board210-850gsm , B/C/E/F flute corrugated board |

| Max method | Automatic continuous feeding |

| Max mechanical speed | 300m/min |

| Overall dimension | 15000*1900*1650mm |

| Weight | 8.6T |

| Power consumption | 14KW,380V,50HZ |

| Compressed air | 6 bar,10 m³/h,60 L |

| Main motor | GPG |

| PLC | Siemens |

| Inverter | Siemens |

| Touch screen | Siemens |

| Driving Bearing | NSK |

| Plain belt | NITTA Japan |

| Low voltage apparatus | Schneider( Relays, contactor,breaker,Button) |

| Air cylinder | AIR TAC Taiwan |

| Photo Switch | Panasonic |

| Wall thickness | 20m (right side,left side) tempered |

| Gluing system | KQ CHINA |

| Servo motor | Delta (Taiwan) for back fold |

1.Feeder Section

· Friction feeder. Independently driven by inverter.

Adjustable electronic pile vibrator.

· Lateral feed gates fully adjustable to the width of the blank.

2.Paper Alignment System:

Independent section that registers the blank to one side ensuring a perfect parallelism before entering the pre-folding or gluing sections.

Independently driven by motor.

Possibility to register on any side of the machine.

Fast and easy setup.Configuration reducer, different boxes when the conversion, the reducer with electric regulation

3.Pre-fold Section: (option)

The pre-fold section has the advantage to make the box more plain and easy to open,even in some case the scoring is not very well.Left hand glue flap pre-folder up to 180º.

3rd crease pre-folding set up to 135º.

1st and 3rd crease openers.

Configuration reducer, different boxes when the conversion, the reducer with electric regulation

4.Bottom Lock Section (option )

Lock-bottom assembly mechanism with high elastic hookers is of deal design,fast and easy operation.

·Independently driven by motor.

Complete set of folding hooks and helixes for smooth and accurate folding of front flaps

Adjustable hook tension.

Fast and easy setup

Configuration reducer, different boxes when the conversion, the reducer with electric regulation.

5.Down Gluing section

·Two lower (left and right) gluing tanks.

·Easy to remove and clean.

6.Folding Section

Independently driven by motor.Smooth and accurate folding of 2nd and 4th creases.

Outer folding belts adjustable up to 180º with variable speed controlled by inverter

Easy accessibility.

7.Trombone Section

· Independently driven by motor.· Upper and lower drive mechanism for length adjustment.

·Allows a perfect understack or overstack stream of boxes.

·Equipped with automatic belt tension-adjusting system.

·Continuous and automatic box collection mechanism that ensures a neat transfer to the Press section, guaranteeing an aligned flow.

8.Press Section

·Independently motorized pneumatic press section.

· Upper section moves back and forward through a motorized system, allowing different box length.

· Pneumatic pressure regulation.

9.Back-folding device(option)

·Motorized and untimed electronic back folding system with intelligent servo-motor technology.·Two independent servo motors, one for each shaft.

·Versatile and easy to setup.

Gluing system

1. Main technical parameter:

Model HZ4

| Input voltage | AC220V (±20%)50-60HZ |  |

| Power | 480W | |

| Glue-like precision | ±1mm | |

| Gel-point | 4 types | |

| Model | HB6 | |

| Guns | 3 | |

| To adhesives max viscosity | 3000mPas | |

| Each two-way transport efficiency | 6:1 | |

| Gas source input requirements | 2-8bar | |

| Weight | 25kg | |

| SIZE | 1280*480*600mm |

Plasma Surface Treatment

Main technical parameter:

| Model | CLEAN-PL-5020 |  |

| Input voltage | AC220V | |

| Nominal power | 1500AV | |

| Plasma power supply frequency | 20-30khz | |

| Air supply pressure | 60L/m³ | |

| Dimension | 720*970*1270 | |

| Outlet angle | <20mm | |

| 2 guns | ||

| Weight | 95kg |

>>> RFQ

1.Q:What is the machine warranty?

A:one year.

2.Q:Does your machine with CE certificate?

A:Yes.we do.

3.Q:What is the production time while placing order?

A:About 30 days.

4.Q:What is the delivery time?

A:Within 30 days after get the payment.

5.Q:Can your company handle shipping for customers?

A:Yes.(Please provide us your requested seaport and we can check the shipping charge and arrange shipping for your order)

6.Q:How about after-sales service process?

A:When your machine has problem, contact your sales and we will solve your problem soon as possible.

7.Q:Are you manufacturer?

A:Yes, we are manufacturer with 10-year experience and profession.

8.Q:Do you have stock product to sell?

A:Actually our machine need 20-30 days to manufacture, and there are many orders from China and foreign countries, so we need custom one for you, and your order will be highly attention to manufacture.

9.Q:Do you inspect the finished products?

A:Yes, we have QC department, they will inspect the machine before shipping, to ensure there is nothing problem of the machine .

10.Q:What's the payment term?

A:T/T 30% in advance, the balance paid before delivery. We also accept payment via West Union and L/C.

11.Q:Are you a trading company or factory?

A: We are the manufacturer and also we have import export license. We have specialized in folding gluing and window patching machine producing for more than 10 years.

12.Q:Where is your company located? How can I visit there?

A:Our new factory address: No.88 Lindong Road,Dongshang Industrial Area,Ruian City.Zhejiang province,China. Zhejiang Zihong Printing Packaging Machinery Co., LTD

13.Q: Can you send technician for installation and training?

A:Yes, we can send our technician abroad for installation and training, but all the charges must be paid by buyer, such as the plane tickets (around trip), meals, hotel, traffic etc.

14. What's your advantages ?

--Rich experience and profession.

--Customers all over the world

--Certificate: CE certificate

--Fast reply:Our team will reply you soon.

--Aftersale service:We have a after sale department, service for your problems and dealing with spare parts.

Any Need ,PLS send inquiry to us, we will be of service at any time.^•^ ^•^ ^•^