WD67K series Electro Hydraulic Servo CNC press brake

[WD67K-125T/3200]

[WD67K-125T/3200]

Production description

Product Type: CNC 63T/2500 CNC steel plate hydraulic press brake

Bending Material: Metal/ Stainless Steel /Carbon Steel /Aluminum

Backgauge range: 500-800

Bending precision: +-0.01

Safety Standard: Europe CE/South America

Control Axes: Y1 + Y2 + X + R, V-axis Crowing (optional)

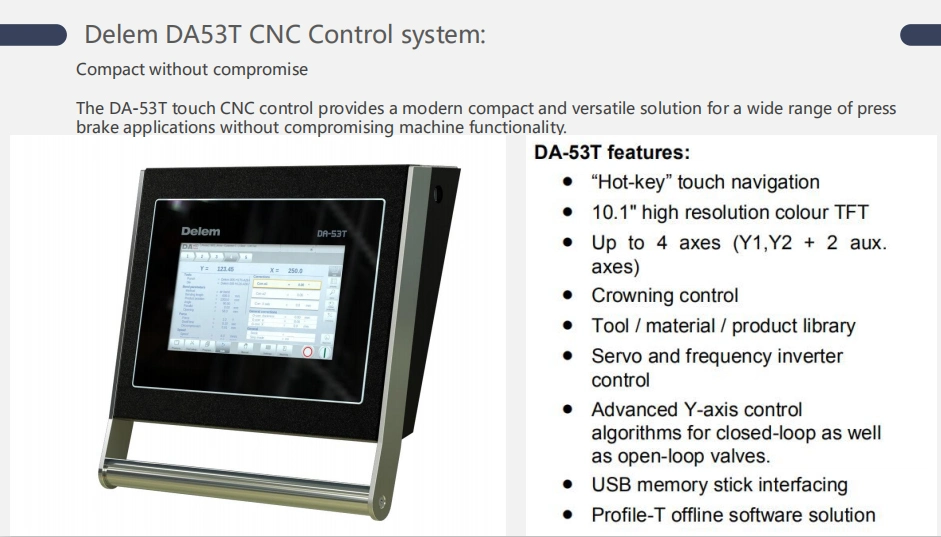

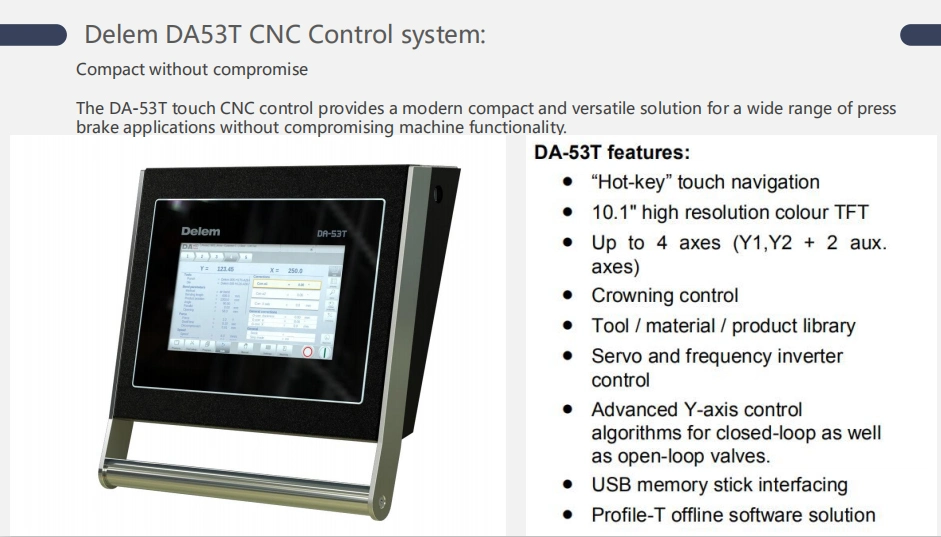

Controller: Delem DA53T

After-sales: Service Engineers available to service machinery overseas

Product Type: CNC 63T/2500 CNC steel plate hydraulic press brake

Bending Material: Metal/ Stainless Steel /Carbon Steel /Aluminum

Backgauge range: 500-800

Bending precision: +-0.01

Safety Standard: Europe CE/South America

Control Axes: Y1 + Y2 + X + R, V-axis Crowing (optional)

Controller: Delem DA53T

After-sales: Service Engineers available to service machinery overseas

Detailed description

Technical analysis

Features of Product

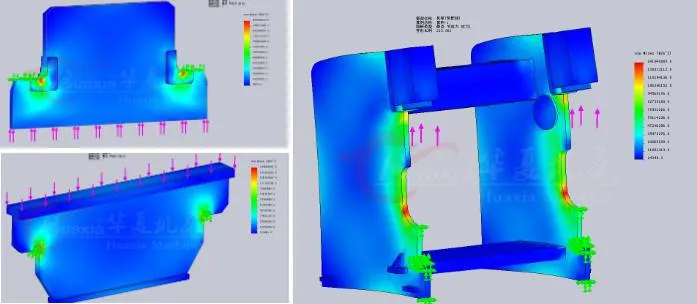

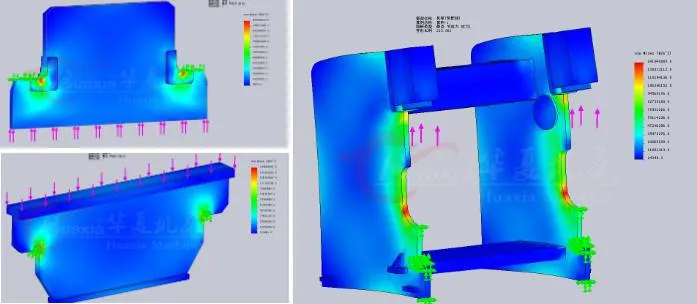

1 The machine body is in an overall welded and overall processed structure, and ANSYS finite element analysis software is applied to main parts of the machine body for analysis, which has ensured the reliability of the machine and the precision of entire machine.

2 The numeric control system adopt Netherland DELEM, Swiss CYBELEC or Italian ESA Companies and so. able to achieve the functions of graphic programming for bending angle, compensation for angle amendment, automatic calculation also adjustment of bending pressure, automatic calculation of compensation for workbench distorsion, extending length of workpieces, bending pressure for sole pressing, open distance, and automatic withdrawal of rear stopper, etc.

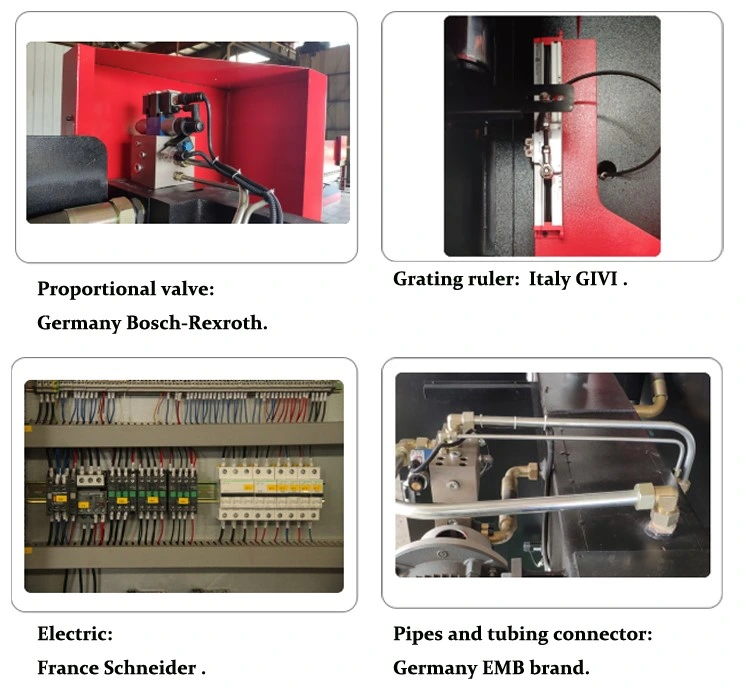

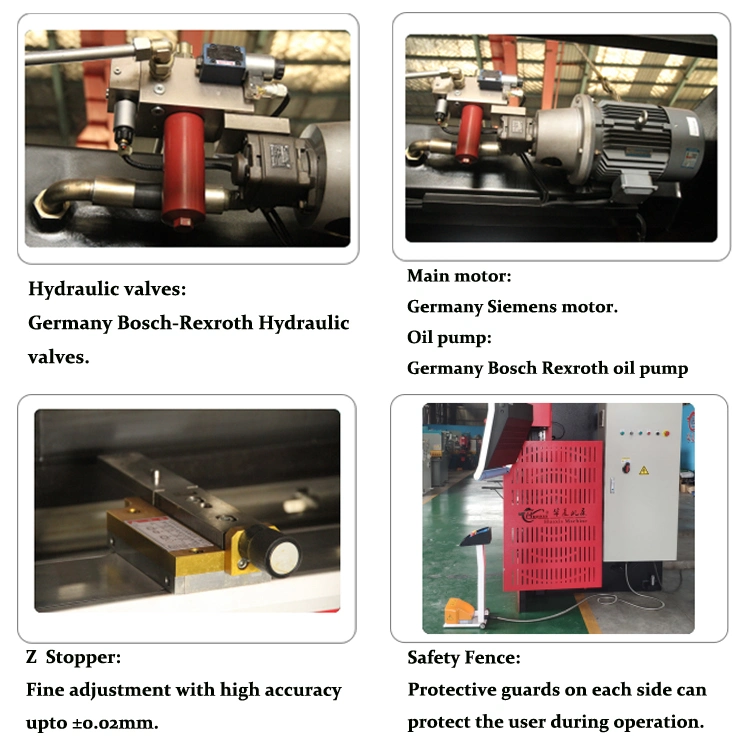

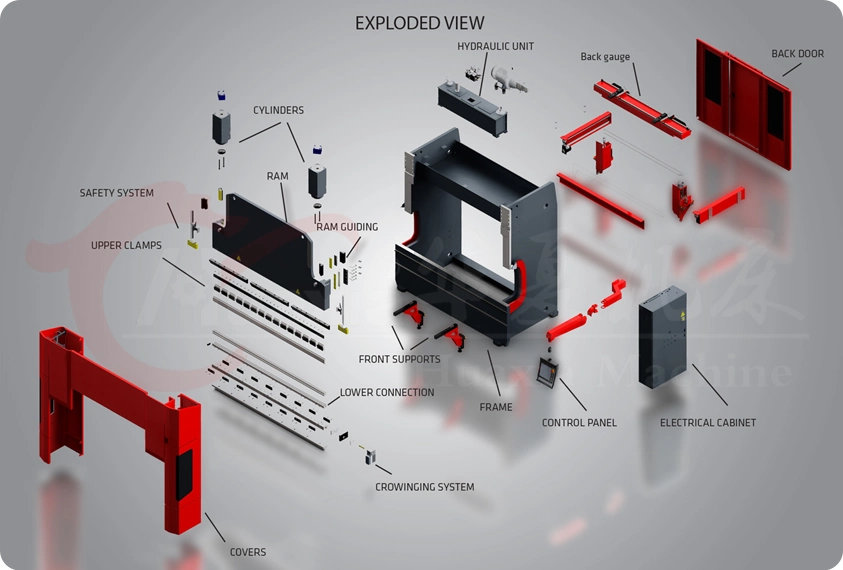

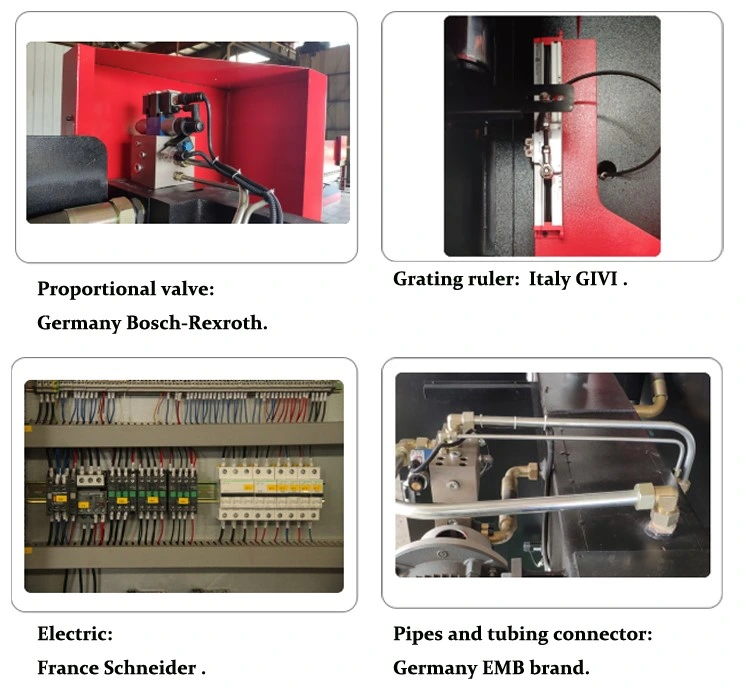

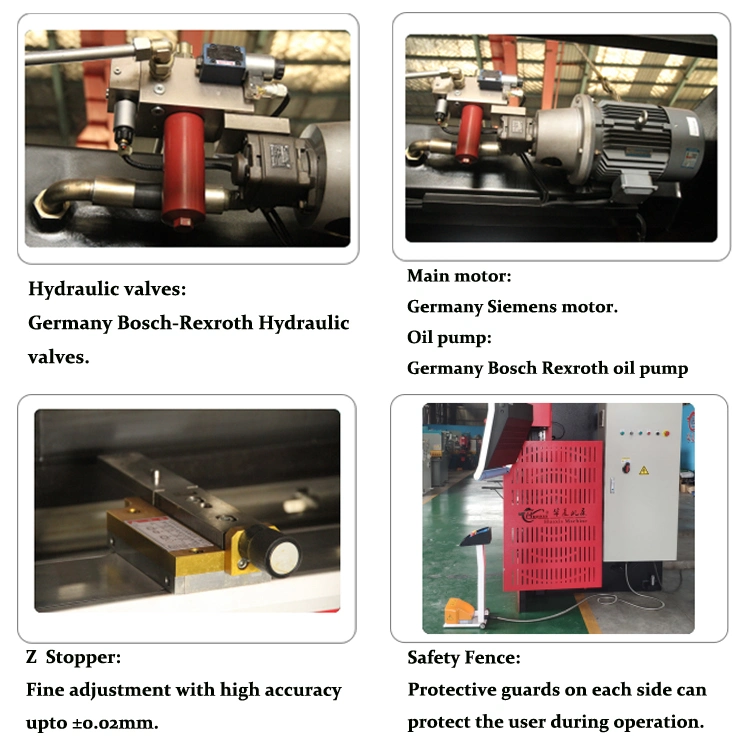

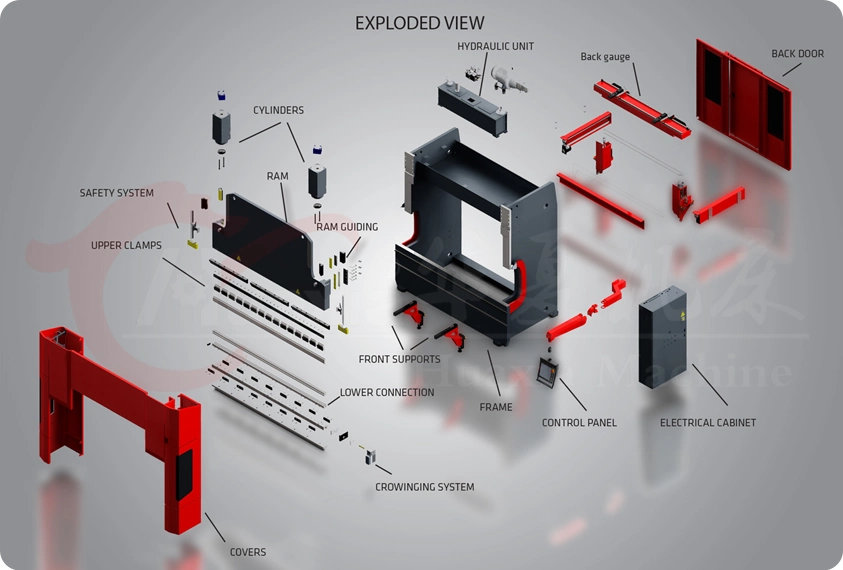

3 Totally EU streamlined design,Monoblock by welding robots & aparatus and stress relief process by Annealing treatment Adopt integrated hydraulic system, more reliable and easy for maintenance. and the hydraulic system from Bosch-Rexroth, Germany.

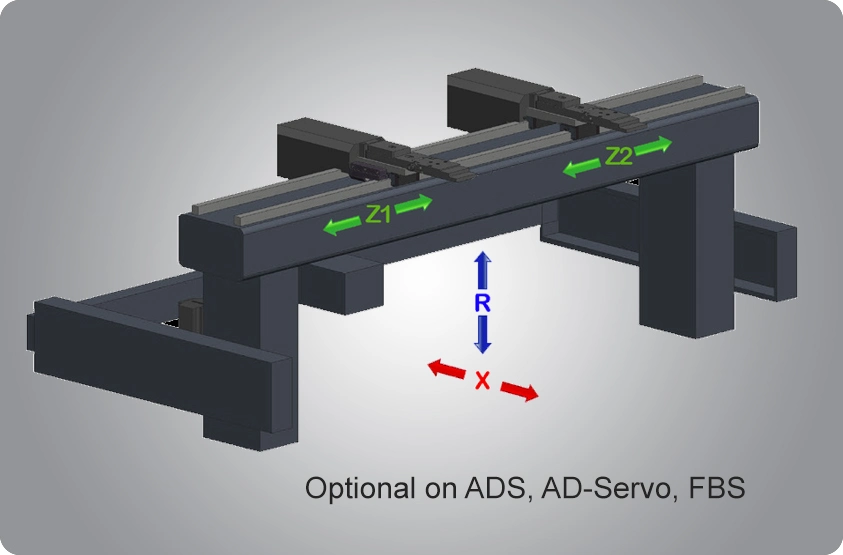

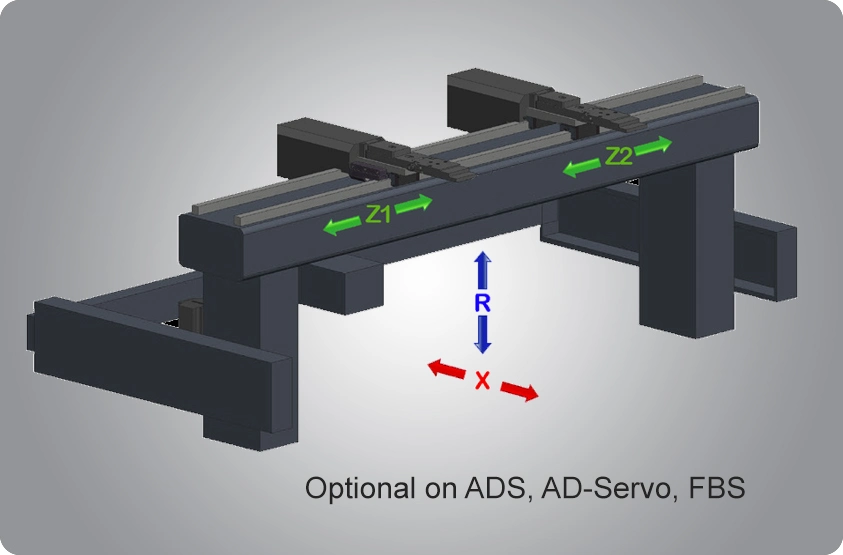

4 Electro-hydraulic servo CNC, Y1, Y2,for Oil cylinder stroke X, R, Z1, Z2 for back gauge ,V for compensation. 6 + 1 axis The stroke and distance of the back gauge is adjusted by the motor and is well adjusted by hand,the adjustment is displayed by DA66T.

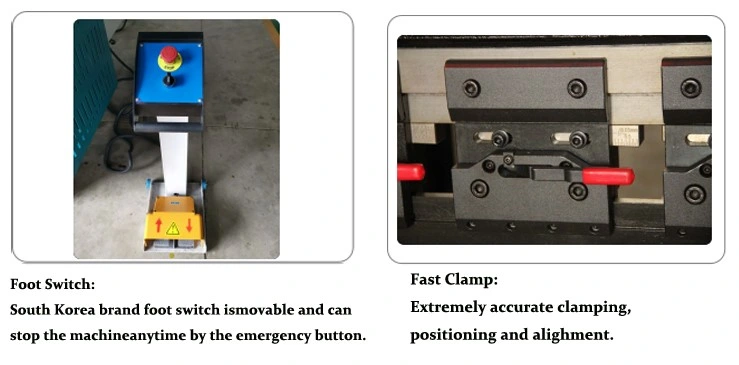

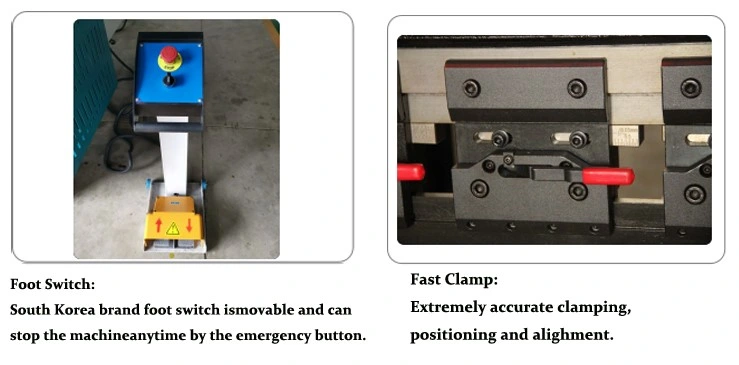

5 Inch, single mode being designed for the machine and reversing and maintain time can be controlled by the time relays. Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety

Our service

2 provide solution in 1 day machines. We dispatch technician to customer's of how to use our machines. As well, you may send your technician

3 solve complaint in 2 days factory for installation and preoperation of machines. to our company to learn how to operate machines.

( Customers only need to pay the airfare and hotel )

FAQ

Technical analysis

Model | Bending length | Poles distance | Throat depth | Slider travel | Main motor | Dimension |

63T/2500 | 2500mm | 1900mm | 350mm | 150 | 7.5 | 2700*1450*2050 |

80T/3200 | 3200mm | 2600mm | 350mm | 200 | 7.5 | 3500*1550*2100 |

100T/3200 | 3200mm | 2600mm | 400mm | 200 | 7.5 | 3500*1580*2400 |

100T/4000 | 4000mm | 3040mm | 400mm | 200 | 7.5 | 4300x1850x2700 |

160T/3200 | 3200mm | 2600mm | 400mm | 200 | 11 | 3500*1650*2500 |

Features of Product

1 The machine body is in an overall welded and overall processed structure, and ANSYS finite element analysis software is applied to main parts of the machine body for analysis, which has ensured the reliability of the machine and the precision of entire machine.

2 The numeric control system adopt Netherland DELEM, Swiss CYBELEC or Italian ESA Companies and so. able to achieve the functions of graphic programming for bending angle, compensation for angle amendment, automatic calculation also adjustment of bending pressure, automatic calculation of compensation for workbench distorsion, extending length of workpieces, bending pressure for sole pressing, open distance, and automatic withdrawal of rear stopper, etc.

3 Totally EU streamlined design,Monoblock by welding robots & aparatus and stress relief process by Annealing treatment Adopt integrated hydraulic system, more reliable and easy for maintenance. and the hydraulic system from Bosch-Rexroth, Germany.

4 Electro-hydraulic servo CNC, Y1, Y2,for Oil cylinder stroke X, R, Z1, Z2 for back gauge ,V for compensation. 6 + 1 axis The stroke and distance of the back gauge is adjusted by the motor and is well adjusted by hand,the adjustment is displayed by DA66T.

5 Inch, single mode being designed for the machine and reversing and maintain time can be controlled by the time relays. Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety

Our service

1.Standardization of Service "212" Installation Service Training Service

1 response in 2 hours Installation Services are available with all Our technician is available to your factory and offer training2 provide solution in 1 day machines. We dispatch technician to customer's of how to use our machines. As well, you may send your technician

3 solve complaint in 2 days factory for installation and preoperation of machines. to our company to learn how to operate machines.

( Customers only need to pay the airfare and hotel )

FAQ